What is electric cylinder?

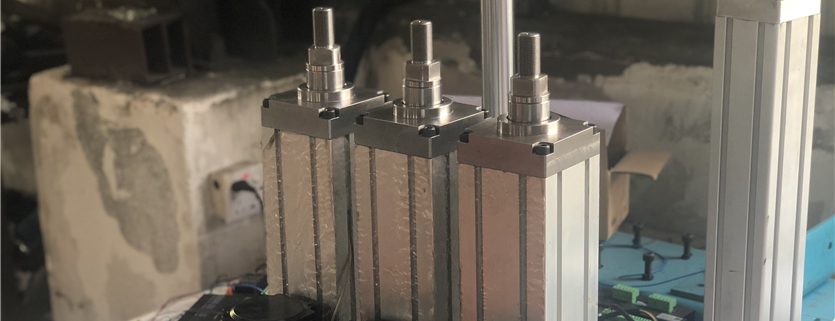

The electric cylinder is a device that use various motors (such as servo motors, stepper motors, BLDC) to drive various screws (such as slide screws and ball screws) to rotate, then it converts into linear motion by nuts, and pushes the slide table along various guide rails (such as sliding guide rails, ball guides, and high-rigidity linear guides) like a cylinder that performs reciprocating linear motion, and it’s a completely new revolutionary product for realizing high-precision linear motion series.

The structure of the electric cylinder is relatively simple, mainly including four parts: drive mechanism, deceleration device, linear transmission mechanism, and auxiliary mechanism.

(1) Drive motor type: DC motor, AC motor, stepper motor, servo motor, etc.

(2) Deceleration devices: general gear reduction, worm gears, planetary gears, harmonic deceleration

(3) Linear actuator: trapezoidal screw, Ball screw, roller screw, the slide guide

(4) Classification of Electric Cylinder: according to the type of installation, electric cylinders can be divided into three types: linear, reentry, and vertical

The linear type is that the electric motor and the screw spindle are installed on the same axis;

The reentry type is where the motor is installed in parallel with the axis of the screw;

The vertical type is that the axis of the motor and the axis of the screw are perpendicular to each other.

Electric cylinder application:

With more and more requirements for factory automation, electric cylinders are used more and more widely. The main applications are as follows:

- The entertainment industry (multi-degrees of freedom simulation, multi-degree freedom dynamic entertainment, robot arm and joint, dynamic seat, etc.)

- Iron and steel industry (widely used in coal unloading, ore unloading, ash unloading, belt conveyors and dust collectors device, etc. at working place like raw material terminals, raw material plant, sintering plants, coking plants, ironworks, steelworks, etc. )

- Other industrial industries (mechanical automation production lines, petrochemicals, material handling, injection molding machines, mold control, valve control, precision machine tools, pharmaceutical machinery, precision machining with multiple degrees of freedom, mechanical lifting platforms, food industry, etc.)

- Automotive industry (automotive presses, automotive manufacturing equipment, etc.)

- Military industry (analogue aircraft, simulation, etc.)

Leave a Reply

Want to join the discussion?Feel free to contribute!