Principle of Electric Linear Actuator and How It Works

The working principle of electric linear actuator is it’s of modular design which integrates the motor and the screw, converting the rotary motion of the motor shaft into the linear motion of the piston rod of the electric linear actuator. Meanwhile, a servo electric linear actuator transforms the advantages of the servo motor—precisely speed,rotation,torque control into—precisely speed,position,thrust control for the purpose of realizing high-precision linear motion revolutionizing products.

The functions of electric linear actuators( or often said electric cylinders) are the same as that of the pneumatic cylinders and the hydraulic cylinders. They are all used in the equipment which requires lifting, pushing and pulling an object. The biggest difference is that electric linear actuator doesn’t not require a compressor or a hydraulic station, it can be driven as long as there is electricity.

Comparing with pneumatic cylinders and hydraulic cylinders, electric linear actuators are of high efficiency, low noise, clean and zero-pollution in operation. Besides that, electric linear actuators can reach precise positioning, which makes it a perfect replacement of the pneumatic cylinder and the hydraulic cylinder.

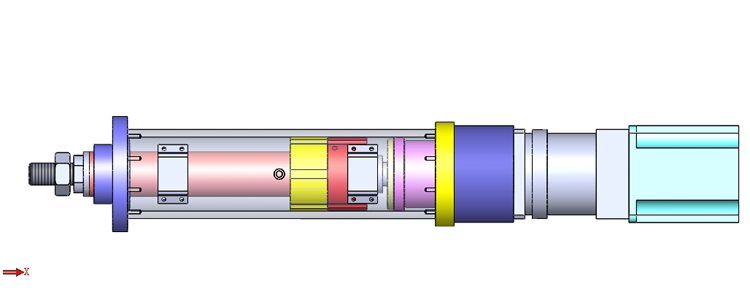

The servo electric linear actuator is mainly composed of a servo motor, a cylinder housing, a motion drive device (normally ball screw) and a position feedback device,etc. The basic principle of the servo electric linear actuator is that the computer sends commands to the servo driver, and servo motor will work under these commands, which drives the ball screw or the trapezoidal screw to rotate through the transmission mechanism such as the gear box or synchronous pulley or coupling.

The screw nut limits the motion radially, it is reciprocating linear motion with the piston rod driven by the rotating torque of the ball screw or lead screw. As for position feedback device, an absolute encoder will be installed at the end of the screw or a PNP/NPN type magnetic switch was installed to detect the real-time position of the electric cylinder piston rod.

Electric linear actuator is a new revolutionary product which can realize high-precision reciprocating linear motion. Electric linear actuator replaces pneumatic cylinder and hydraulic cylinder in more and more fields, and it is convenient for electrical control. It is widely used in industrial equipment, motion platforms, such as opening and closing doors, lifting, pushing and pulling, and precise positioning. The thrust of the DGR electric linear actuator ranges from 5kg to 20 tons.

If you should be afraid of creating monetary deals to the websites, you merely have

to check the safety dilemmas of the sites.