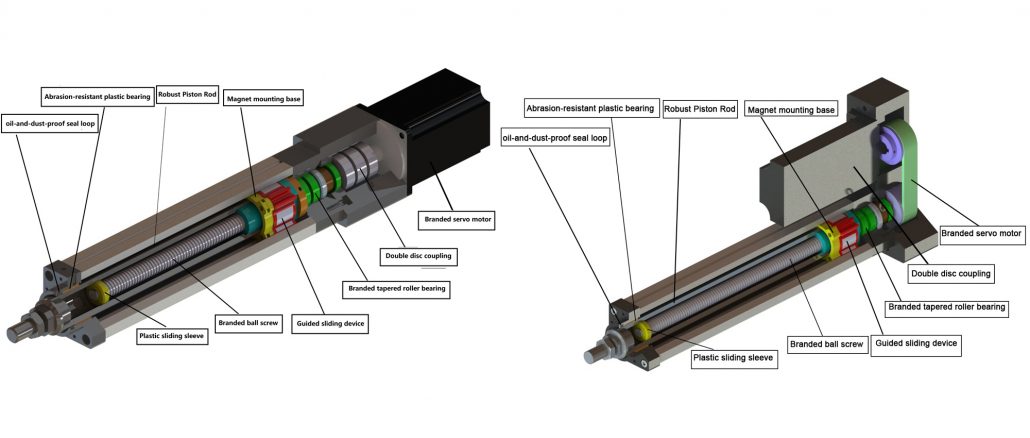

Discover The Inside of Electric Cylinders

The Structure of Electric Cylinder:

The electric Cylinders are mainly composed of several parts:

1.Motor: various kinds of motors are applicable (such as DC or AC servo motor, stepper motor, DC brushless or brushed motor).

2.Ball screw or trapezoidal screw. It’s rotated by the motor and converted the the spiral motion into the linear motion of piston rod. And then the robust piston rod force the load to make the reciprocating linear motion.

3.It is equipped with anti-rotation mechanism inside, which make a convenience usage.

4.The internal magnetic ring mechanism works together with external sensor switches of the electric Cylinder as a complete position feedback device and limits the reciprocating motion positions on both ends.

5.A pair of high-strength tapered roller bearings are equipped inside, which meet applications requiring equivalent push and pull force;

6.Sealed with oil-proof and dust-proof ring, prevents dusts from getting inside and keep the lubrication grease from leaking.

7.During the reciprocating linear movement, the durable plastic sliding sleeve and the guiding sliding device protects of the internal structure from abrasion.

8.Coupling/synchronous pulley structures: while the servo motor rotates, the ball screw or trapezoidal screw is rotated by the transmission mechanism by synchronous pulley or coupling, with or without a gear box in between.

Other Optional Parts:

1.Load sensor, a device converts the thrust value into an associated electrical signal. Thrust is the direct cause of motion of an object. The thrust sensor detects mechanical forces such as tension, pressure, weight, torque, internal stress and strain.

2.Torque feedback devices : this function can be added to motor for a precise torque control.

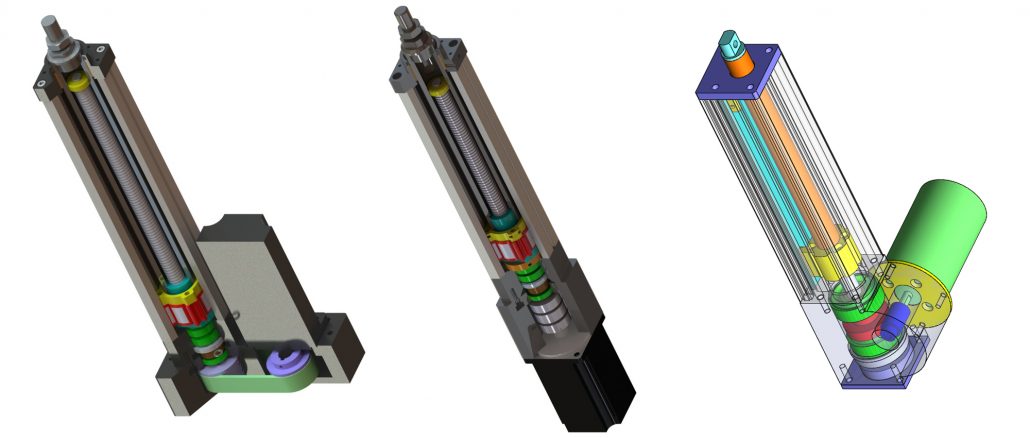

The electric Cylinder can be divided into three types by appearance: an inline type electric Cylinder, a parallel type electric Cylinder, and a vertical type electric Cylinder and the former two are the most commonly used. However,vertical type electric Cylinders can be customized and designed according to customers’ requirements.

The electric Cylinder can be divided into three types by appearance: an inline type electric Cylinder, a parallel type electric Cylinder, and a vertical type electric Cylinder and the former two are the most commonly used. However,vertical type electric Cylinders can be customized and designed according to customers’ requirements.

Leave a Reply

Want to join the discussion?Feel free to contribute!