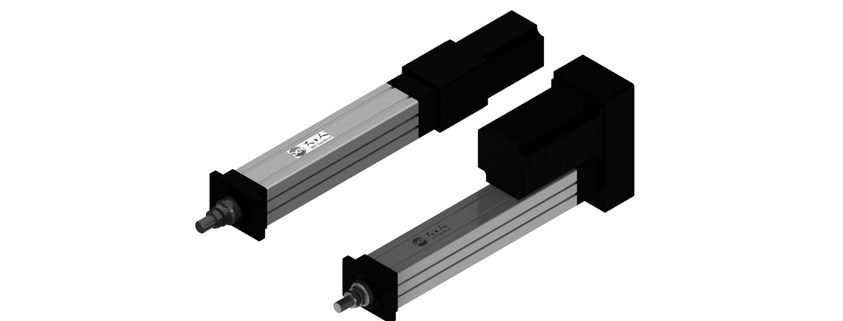

Features of DGR Electric Linear Actuators

DGR electric linear actuators featured at being produced at the highest standards with carefully seleted materials to meet customers’ requirements for the life span and positioning precision, all the parts are machined by CNC machines, with compatibility with motors from all manufacturers in the world. | |

| High Accuracy High precision, the processing of key parts is completed by CNC machining, and the machining accuracy is within 0.02mm. | High Reliability Highly reliable, safety factor>2 ( PS: safety factor for key parts > 4), which is in compliance with metallurgical standard. |

| Long Life Run over a distance of 100,000km | Complete Testing Professional factory inspection: including appearance, mechanical properties, stability, noise decibels, etc. |

| Duty Cycle Ball screws are used for frequent operation of electric cylinders, the duty cycle is ensured to be greater than 50% or continuous operation.

| Wide Thrust Range Select famous branded roller ball screws, ball screws and lead screws which are made of high-quality materials for our electric cylinders in order to reach double the theoretical rated push-pull force. |

| Careful Material Selection 1. Select aluminum alloy as the cylinder material, simple and light, beautiful appearance 2. Select sensor components of internationally famous brands . 3. Key components are made of high quality materials and processed with vacuum heat treatment or surface treatment (including: coating, azotizing, oxidation) 4. Select branded bearings and gears to achieve the best mechanical performance in mechanical structure 5. Select high-quality grease to minimize friction, which enables the drive efficiency to reach up to 90%. | Refined Design and Processing 1. The connection between the screw nut and the piston rod is rigid 2. Snap fastener will be required to locate the part in its fixed position to avoid assembly errors that affect mechanical properties. 3. All screw threads are coated with screw locking adhesive after commissioning to ensure the equipment is stable and trouble-free. 4. Electric cylinder comes with anti-rotation mechanism by default 5. Professional machining processing equipment minimizes the cost.

|

| Wide Selection of Motors 1. A variety of AC servo motors or stepper motors for option: such as Delta, Mitsubishi, Panasonic, Yaskawa and other brands 2. Motor comes with brake to ensure secure operation. | Excellent Service 1. Each DGR electric cylinder is backed by a lifelong tracking service to ensure it can be used normally over its life cycle. (including: handling product failure, providing spare parts and technical support) 2. DGR Electric cylinder can be custom engineered for customer’s particular application. 3.5 years’ experience in electric cylinder production. 4.All customer requirements will be responded within 12 hours |

Leave a Reply

Want to join the discussion?Feel free to contribute!