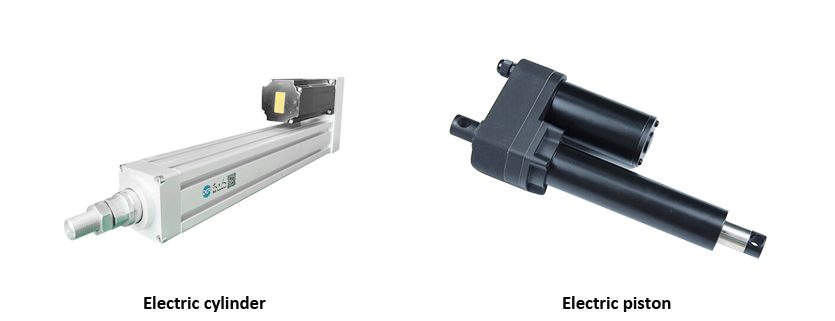

Difference between electric cylinder and electric piston

Electric cylinders (also called linear actuators, electric actuators) and electric piston (also known as electric lift ram, electric ram) are also generally referred to as electric linear actuators. The electric motor drives various screw rotations to convert the nut into a reciprocating linear motion. In general, The working principle of the two is the same, it is the movement of linear push-pull and lift action, but strictly speaking, there are still many subtle differences between the two. The specific analysis is as follows:

1.Structure

- The nut inside the electric pistonis an ordinary nut, and there is always a large gap between the rod and nut in the internal structure. The motor used is mostly an AC and DC motor, so the position repeatability is low and the service life is short;

- The electric cylinder adopts the motor as the servo motor or the stepping motor, and its internal junction gap is almost zero. Therefore, the electric cylinder has high position repeatability, it can repeatably move to any position after programming, and it comes with moreapplications and long service life (up to 100000Km or more).

Typical position repeatability

AC electric piston accuracy: 0.2mm, DC electric piston accuracy: 1-2mm

Electric cylinder: 0.01-0.02mm

2.Material

- The electric pistonis made of a common trapezoidal screw and a ball screw, and is usually connected to a gear motor and a turbine rod for transmission, so the efficiency is relatively low;

- Electric cylinders are usually made of ground ball screws and planetary ball screws. They are directly coupled to the motor or synchronously connected to the pulley, which is very efficient.

Speed:

The speed of the electric piston is generally <100mm/s

Electric cylinders up to 2m/s

3.Control

- The electric piston can only control the two positions of 0 point and maximum stroke;

- The electric cylinder can be started and stopped at any position.

4.Thrust

- The electric pistonis mainly to realize the push-pull action, and the maximum thrust is basically difficult to exceed 10 tons;

- Electric cylinders, such as servo electric cylinders, canprovide thrust up to 35 tons or more.

All in all, the electric piston has a simple structure, low thrust, low working cycle, simple control procedure, low price, and is used for performing mechanical use in various simple or complicated processes;

As for electric cylinders, especially servo electric cylinders are more widely used in various industries. Generally speaking, it has large thrust, large stroke, precise speed and position control, and its price is higher than electric piston

Leave a Reply

Want to join the discussion?Feel free to contribute!